1. Izinto:Uzibuthe we-Neodymiumngekhwalithi ephezulu yokusebenza kanye nebanga + Insimbi ye-carbon ephansi

2. Ukwelashwa okungaphezulu: I-Zinc, i-Ni+Cu+Ni, noma i-epoxy ye-Neodymium uzibuthe + i-Zinc, upende noma obunye ubuchwepheshe obudingekayo bekesi lensimbi

3. Iphakheji: ipakishwa ebhokisini likathayela bese kuthi amabhokisi apakishwe kuphalethi yokhuni noma ikesi. Isiqephu esisodwa, ezimbili, ezintathu noma ezinye ezisekelwe kusayizi webhokisi likathayela ngalinye

4. I-Lever yokuphakamisa: Ukuphakamisa i-lever mahhala uma inani le-oda likazibuthe wokuvala likhulu futhi kulula ukulithumela ndawonye

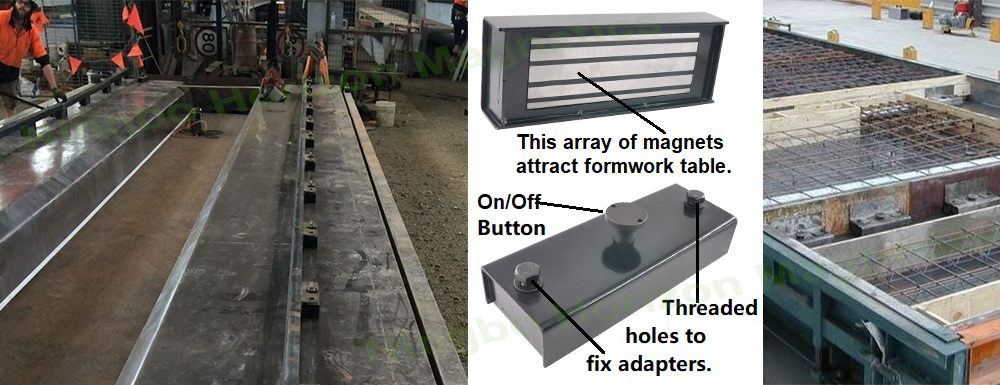

1. Izitshalo ze-Precast ezinesistimu yokukhiqiza emile ukuze zikhiqize izinto zikakhonkolo ezisakazwa ngaphambili, njengama-slabs aphansi noma izindonga eziphindwe kabili

2. Amafekthri e-Precast ukukhiqiza izimbobo eziyinkimbinkimbi noma ezincane, njengeminyango noma amafasitela adinga izibuthe eziningana zokuvala ukuze abophe amafomu.

3. Izinkampani ze-Precast zikhiqize ezinye izimo ezikhethekile zezakhi ze-PC ngokwesibonelo irediyasi, ezidinga izibuthe ezimbalwa zokuvala esikhundleni sohlelo olude lokuvala ukuze lufake iphrofayili yefomu.

4. Noma yiziphi izinkampani ngaphandle kwemboni ye-precast ezicabanga ukuthi uzibuthe wokuvala ungahlangabezana nemfuneko yazo mayelana namandla okubamba okuphezulu nokusebenza okulula.

1. Iguquguquka cishe nazo zonke izinto zokwakha, njengezinkuni, insimbi noma i-aluminium

2. Uzibuthe ofanayo ukuze uhlangabezane nezinhloso ezahlukene ekuqiniseni ama-formworks

3. Osayizi abengeziwe namandla asukela ku-450 Kg kuya ku-3100 Kg ukuhlangabezana nezidingo zakho ezihlukahlukene

4. Usayizi ohlangene, ukukhanya futhi kulula ukuyisebenzisa

5. Ukuma okulula nokuqondile

6. Gwema ukushisela noma ukufaka ibhawudi etafuleni le-formwork ngakho-ke ulondoloze ukuphela kwendawo

7. Izimbobo ezimbili ezinentambo ezihlanganisiwe ukuze zivumelane ne-formwork

Cindezela inkinobho eshintshekayo phezu kwekesi lensimbi ukuze uvule amandla kazibuthe ukuze uqinise i-formwork etafuleni lensimbi ngokuqinile. Sebenzisa i-lever ephakamisayo ukudonsa inkinobho ukuze uvale amandla kazibuthe ukuze unyakaze futhi ubeke izibuthe zokuvala bese ulungisa ama-formworks. Kwesinye isikhathi, sebenzisa izimbobo ezinentambo ezihlanganiswe phezulu kuzibuthe wokuvala ukuze unamathisele ama-adaptha ahlukahlukene, ukuze uhlangabezane nezidingo ezingenamkhawulo zohlelo.

1. Amandla okuncintisana angenakuqhathaniswa engxenyeni ebaluleke kakhulu, uzibuthe we-Neodymium, ngoba i-Horizon Magnetics ivela futhi namanjeUkukhiqiza uzibuthe we-Neodymium

2. Ukuqiniseka ngekhwalithi nokwamukela imigomo yokukhokha efana no-100% T/T ngemva kokuthola kwamakhasimende omazibuthe bethu abavalayo

3. Ukunikezwa okuphelele kozibuthe bakakhonkolo abangaphambili njengama-chamfer kazibuthe,faka ozibuthe, kanye nekhono lokwenza imishini yasendlini ukukhiqiza imikhiqizo kazibuthe eyenziwe ngokwezifiso ukuhlangabezana nokuthenga kwamakhasimende okukodwa

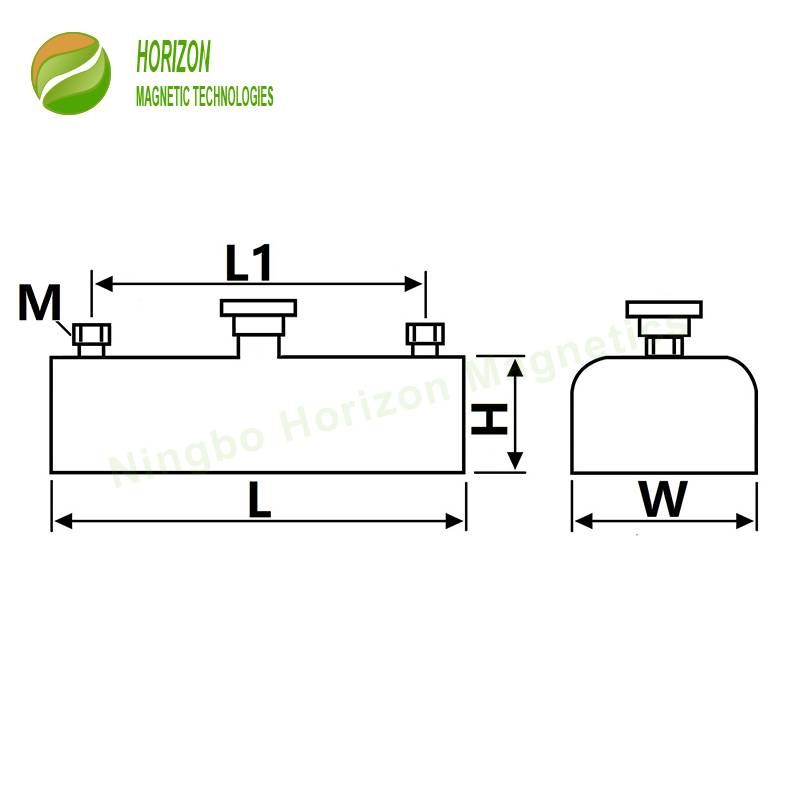

| Inombolo Yengxenye | L | L 1 | H | M | W | Phoqa | Ubukhulu Bezinga Lokushisa Lokusebenza | ||

| mm | mm | mm | mm | mm | kg | lbs | °C | °F | |

| I-HM-MF-0900 | 280 | 230 | 60 | 12 | 70 | 900 | 1985 | 80 | 176 |

| I-HM-MF-1600 | 270 | 218 | 60 | 16 | 120 | 1600 | 3525 | 80 | 176 |

| I-HM-MF-2100 | 320 | 270 | 60 | 16 | 120 | 2100 | 4630 | 80 | 176 |

| I-HM-MF-2500 | 320 | 270 | 60 | 16 | 120 | 2500 | 5510 | 80 | 176 |

| I-HM-MF-3100 | 320 | 270 | 60 | 16 | 160 | 3100 | 6835 | 80 | 176 |

1. Uhlu lwangaphakathi lomazibuthe be-Neodymium kufanele lugcinwe luhlanzekile. Gwema ukhonkolo ukungena ngaphakathi kuzibuthe wokuvala ukuze uqinisekise ukuthi amandla alinganiselwe ahlala futhi inkinobho eshintshwayo isebenza ngendlela eguquguqukayo.

2. Ngemva kokusetshenziswa, kufanele igcinwe ihlanzekile futhi igcotshwe ngamafutha ukuze ivikeleke ekugqwaleni.

3. Izinga lokushisa eliphezulu lokusebenza noma isitoreji kufanele libe ngaphansi kuka-80℃. Izinga lokushisa eliphakeme lingabangela uzibuthe wokuvala wehlise noma ulahlekelwe amandla kazibuthe ngokuphelele.

4. Nakuba cishe awekho amandla kazibuthe azwakalayo ngaphandle kwegobolondo lensimbi likazibuthe ovalayo, amandla kazibuthe ohlangothini olucushiwe aqine kakhulu. Sicela uyigcine ikude nezinsimbi zikagesi nezinsimbi ezingadingekile ze-ferromagnetic. Ukuqapha okukhethekile kufanele kusetshenziswe uma othile egqoke isishicileli senhliziyo, ngoba amandla kazibuthe anamandla angalimaza izinto zikagesi ezingaphakathi kwezihlinzeki-nhliziyo.