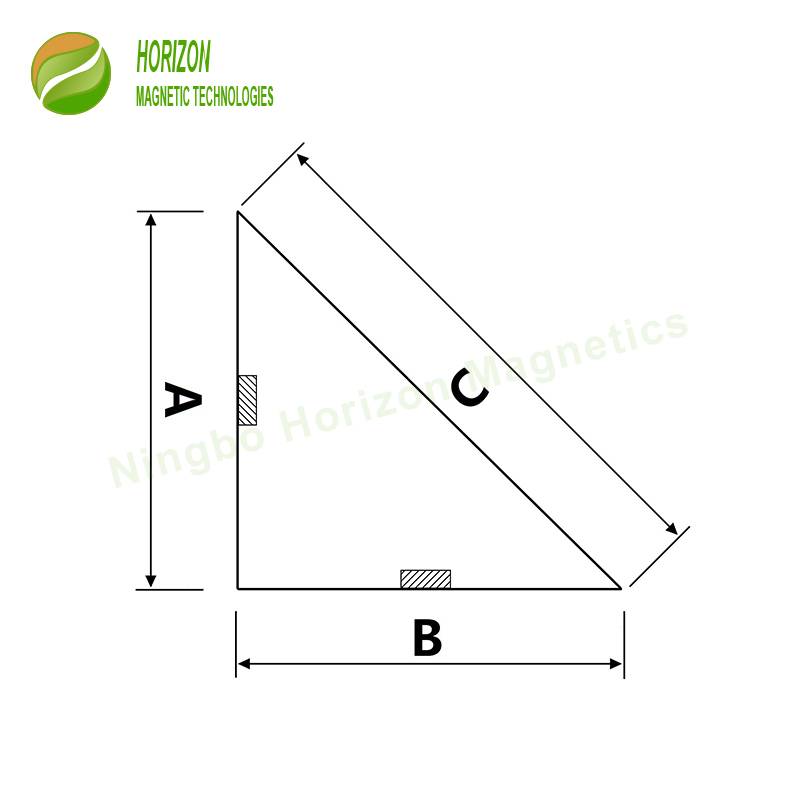

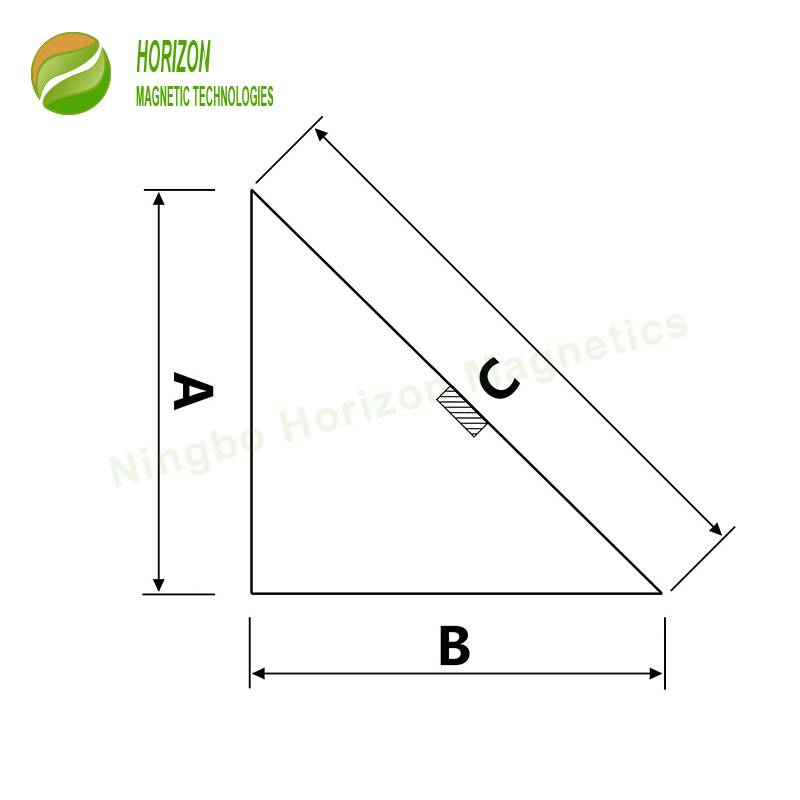

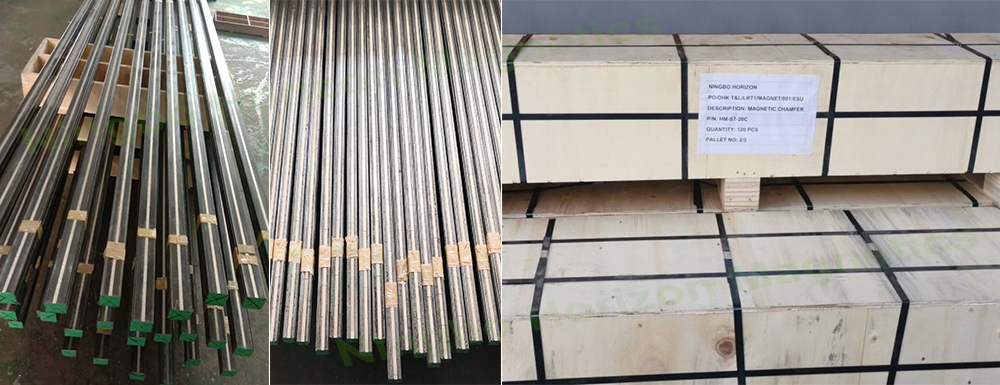

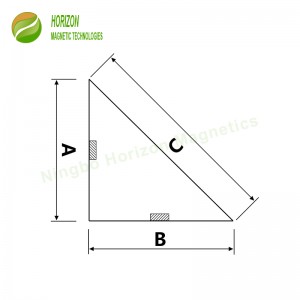

Yakhiwe ngamandlaOzibuthe bebha ye-Neodymiumifakwe ensimbi yekhwalithi ephezulu. Njengoba nje ukwakheka nomgomo wozibuthe besiteshi se-Neodymium, insimbi iqondisa kabusha i-polarity yezibuthe ze-Neodymium isuka kolunye uhlangothi iye kolunye uhlangothi oluthintwayo ngamandla okubamba aphezulu. Ngaphezu kwalokho, omazibuthe abaningi bebha abancane bavikelwe yinsimbi emonakalweni wemishini. Uhlangothi lokuxhumana luvumela ukubekwa okusheshayo nokunembile kwe-chamfer yensimbi ekwakhiweni kwe-steel formwork ngaphandle kokushelela noma ukushelela. I-chamfer kazibuthe ingunxantathu wesokudla omile futhi ingalethwa ngosayizi abahlukahlukene abahlukene ngozibuthe ohlangothini olulodwa, izinhlangothi ezikabili noma i-hypotenuse ngobude obuphelele obungu-100% noma nje ngo-50% wobude.

1. Kulula ukusebenza

2. Isebenziseka kabusha futhi ihlala isikhathi eside ukuze kuncishiswe ukutshalwa kwezimali okwabiwe esikhathini eside

3. Azikho izikulufo, amabhawodi, i-welding noma ugesi odingekayo ukuze ubophe i-chamfer kazibuthe. Ngokushesha ukubeka, susa futhi uhlanze

4. I-Universal enamasistimu amaningi kakhonkolo asakazwa ngaphambili ukuze kwehliswe inani lokuthengwa nezindleko zamasistimu ahlukene

5. Amandla okunamathela anamandla nempilo ende yesevisi kune-chamfer yerabha

6. Ukwenza ngcono umphumela wekhwalithi emikhiqizweni kakhonkolo wangaphambili ukuze kuqedwe izinkinga eziningi zokuqeda isakhiwo

1. Amandla angenakuqhathaniswa okuncintisana kazibuthe kanye nokusebenza embonini kakhonkolo we-precast futhi ujwayele ukuthi yini futhi kanjani ukuqinisekisa ama-chamfer kazibuthe ensimbi,ukuvala ozibuthefuthi ufake omazibuthe ukuze uxazulule ukukhathazeka kwamakhasimende

2. Osayizi abengeziwe abatholakalayo ukonga izindleko zamathuluzi bese kuba yintengo yomkhiqizo kumakhasimende

3. Osayizi abajwayelekile esitokweni futhi batholakalela ukulethwa ngokushesha

4. Izisombululo ezenziwe ngokwezifiso ziyatholakala uma uzicelile

5. Ama-chamfer kazibuthe amaningi adumile kumakhasimende kanye namanye amamodeli ethu abonwa njengedizayini evamile noma usayizi embonini kakhonkolo osakazwa ngaphambili.

| Inombolo Yengxenye | A | B | C | Ubude | Ubude Bezibuthe | Uhlobo Lohlangothi Oluzibuthe | Ubukhulu Bezinga Lokushisa Lokusebenza | |

| mm | mm | mm | mm | °C | °F | |||

| I-HM-ST-10A | 10 | 10 | 14 | 3000 | 50% noma 100% | Awushadile | 80 | 176 |

| I-HM-ST-10B | 10 | 10 | 14 | 3000 | 50% noma 100% | Kukabili | 80 | 176 |

| I-HM-ST-10C | 10 | 10 | 14 | 3000 | 50% noma 100% | Awushadile | 80 | 176 |

| I-HM-ST-15A | 15 | 15 | 21 | 3000 | 50% noma 100% | Awushadile | 80 | 176 |

| I-HM-ST-15B | 15 | 15 | 21 | 3000 | 50% noma 100% | Kukabili | 80 | 176 |

| I-HM-ST-15C | 15 | 15 | 21 | 3000 | 50% noma 100% | Awushadile | 80 | 176 |

| I-HM-ST-20A | 20 | 20 | 28 | 3000 | 50% noma 100% | Awushadile | 80 | 176 |

| I-HM-ST-20B | 20 | 20 | 28 | 3000 | 50% noma 100% | Kukabili | 80 | 176 |

| I-HM-ST-20C | 20 | 20 | 28 | 3000 | 50% noma 100% | Awushadile | 80 | 176 |

| I-HM-ST-25A | 25 | 25 | 35 | 3000 | 50% noma 100% | Awushadile | 80 | 176 |

| I-HM-ST-25B | 25 | 25 | 35 | 3000 | 50% noma 100% | Kukabili | 80 | 176 |

1. Beka i-chamfer kazibuthe kuma-formworks ngobumnene ukuze ugweme odonsa abalinyazwa ukuheha kungazelelwe.

2. Ozibuthe be-Neodymium abashumekiwe kufanele bagcinwe behlanzekile. Gwema i-grout ukumboza omazibuthe ukuze ugcine amandla kazibuthe.

3. Ngemva kokusetshenziswa, kufanele igcinwe ihlanzekile futhi igcotshwe ngamafutha ukuze ivikeleke ekugqwaleni.

4. Izinga lokushisa eliphezulu lokusebenza noma lokugcina kufanele libe ngaphansi kuka-80℃. Izinga lokushisa eliphakeme lingabangela i-chamfer kazibuthe ukuthi inciphise noma ilahlekelwe amandla kazibuthe ngokuphelele.

5. Nakuba amandla kazibuthe we-chamfer kanxantathu wensimbi kazibuthe ephansi kakhulu kunozibuthe ovalayo, asaqine ngokwanele ukudala izingozi kubasebenzi ngokumpintsha umthelela. Ukugqoka amagilavu ukuvikela izandla kunconywa kakhulu. Sicela uyigcine ikude nezinsimbi zikagesi nezinsimbi ezingadingekile ze-ferromagnetic. Ukuqapha okukhethekile kufanele kusetshenziswe uma othile egqoke isishicileli senhliziyo, ngoba amandla kazibuthe anamandla angalimaza izinto zikagesi ezingaphakathi kwezihlinzeki-nhliziyo.