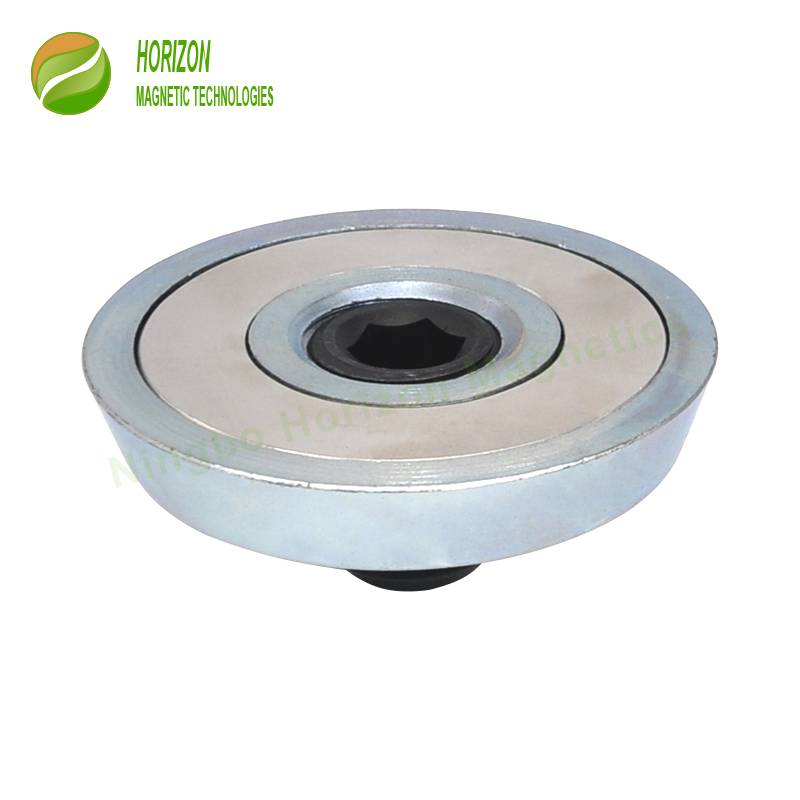

Kuyafana nje neUzibuthe webhodwe le-Neodymium, uzibuthe wokufaka uqukethe uzibuthe wendandatho ye-NdFeB, ikesi lensimbi kanye nenduku enentambo. I-casing yensimbi ivikela uzibuthe we-Neodymium emonakalweni wangaphandle futhi igxilisa amandla kazibuthe we-encased aI-Neodymium ring magnetendaweni ethintwayo kuphela ukukhiqiza amandla aphezulu kakhulu kunozibuthe we-Neodymium ohlukile. Kodwa-ke inamaphuzu athile ahlukene kusuka kuzibuthe ebhodweni ukuze ihlangabezane nemfuneko yohlelo lokusebenza kukhonkolo osakazwa ngaphambili. Ukuma kwe-casing yensimbi kuyacindezelwa futhi induku enentambo iyashintshashintsha ukuze umazibuthe wokufaka ulungele ukudonsa kukhonkolo oqinile ngokusebenzisa isikrufu sesokhethi.

1. Impahla: Uzibuthe we-Neodymium onokusebenza okuphezulu kanye nebanga + Ibhokisi lensimbi nenduku

2. Ukumboza: Umazibuthe umbozwe nge-NiCuNi noma nge-Zinc + isikhwama sensimbi esinamekwe nge-Zinc noma i-Copper

3. Usayizi namandla: Ibhekisela kudatha yobuchwepheshe

4. Iphakheji: Ipakishwe emakhathoni kathayela. Amabhokisi apakishwe ku-pallet yokhuni noma ikesi ngobuningi

1. Amandla kazibuthe kanye nomklamo nesakhiwo esiyingqayizivele kwenza ukukhanya futhi kube lula ukusebenza.

2. Iyasebenziseka kabusha futhi ihlala isikhathi eside ukonga izindleko ezabiwe esikhathini eside.

3. Iyashesha ukubeka futhi ithuthukise ukusebenza kahle kanye nezindleko.

4. Ingathuthukisa ikhwalithi yezakhi zekhonkrithi ze-precast.

5. Amandla kazibuthe aphakeme ngokwanele ukuze amise futhi abophe izingxenye ezishumekiwe ngokunembile phakathi nokusakazwa kukakhonkolo noma inqubo yokudlidliza ukuze unike amandla ukusebenza kokuphakamisa okuphephile.

1. Ulwazi olungahlulwa ku-Neodymium uzibuthe, ingxenye ebaluleke kakhulu yokuqinisekisa ikhwalithi kazibuthe

2. Ulwazi kumagnetics kanye nokwenza kwangaphakathi kusiza amakhasimende ukuthi abone imikhiqizo yamakhasimende kusuka kumqondo kuya emikhiqizweni kazibuthe yokugcina kalula

3. Izitayela eziningi namasayizi atholakalayo ukonga izindleko zamathuluzi nentengo yomkhiqizo kumakhasimende

4. Osayizi abajwayelekile esitokweni futhi batholakalela ukulethwa ngokushesha

5. Complete supply of precast ukhonkolo odonsa kuhlanganiseukuvala ozibuthe, ama-chamfer kazibuthe kanye nemikhiqizo kazibuthe eyenziwe ngokwezifiso ukuhlangabezana nokuthenga okukodwa kwamakhasimende

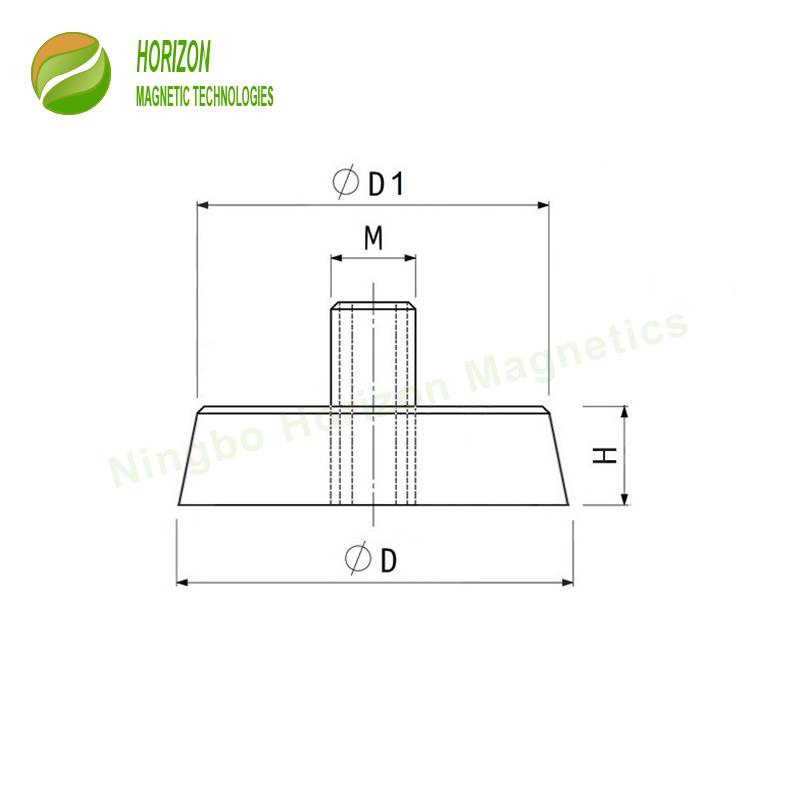

| Inombolo Yengxenye | D | D1 | H | M | Ubukhulu Bezinga Lokushisa Lokusebenza | |

| mm | mm | mm | mm | °C | °F | |

| I-HM-IN45-M8 | 45 | 40 | 8 | 8 | 80 | 176 |

| I-HM-IN45-M10 | 45 | 40 | 8 | 10 | 80 | 176 |

| I-HM-IN54-M12 | 54 | 48 | 10 | 12 | 80 | 176 |

| I-HM-IN54-M16 | 54 | 48 | 10 | 16 | 80 | 176 |

| I-HM-IN60-M20 | 60 | 54 | 10 | 20 | 80 | 176 |

| I-HM-IN77-M24 | 77 | 73 | 12 | 24 | 80 | 176 |

1. Gwema indawo yokumboza i-grout kazibuthe ovalekile we-Neodymium ukuze ugcine amandla kazibuthe.

2. Sebenzisa noma gcina uzibuthe ofaka ngaphansi kuka-80℃. Izinga lokushisa eliphakeme lingabangela ukuthi uzibuthe wehlise noma ulahlekelwe amandla kazibuthe ngokuphelele.

3. Kutuswa kakhulu ukuthi amagilavu kufanele agqokwe ukuze kuvikelwe izandla zabasebenzi ekumpintsheni umthelela. Sicela uyigcine ikude nezinsimbi zikagesi nezinsimbi ezingadingekile ze-ferromagnetic. Ukuqapha okukhethekile kufanele kusetshenziswe uma othile egqoke isishicileli senhliziyo, ngoba amandla kazibuthe anamandla angalimaza izinto zikagesi ezingaphakathi kwezihlinzeki-nhliziyo.