Isiphakamisi sikazibuthe esihlala njalo siyindlela esheshayo, ephephile futhi elula yokuphakamisa amapuleti ensimbi, amabhlogo ensimbi nezinto zensimbi eyicylindrical, njengezingxenye zemishini, isikhunta se-punch nezinhlobo ezihlukahlukene zezinto zensimbi.

Yakhiwe izingxenye ezimbili, i-sucker ehlala njalo kanye nedivayisi yokukhipha. I-sucker ehlala njalo yakhiwe ngozibuthe baphakade be-Neodymium kanye nepuleti le-magnet-conductive. Imigqa yamandla kazibuthe ekhiqizwe ngozibuthe be-Neodymium idlula kupuleti le-conductive kazibuthe, izinto ezihehayo futhi zakhe isekethe evaliwe ukuze kuzuzwe injongo yokuphakamisa izinto zensimbi. Idivayisi yokukhipha isho ngokuyinhloko isibambo. Isetshenziswa kabanzi embonini yemishini, ukukhiqiza isikhunta, izindawo zokugcina izimpahla kanye neminyango yezokuthutha ukuthutha amapuleti ensimbi, izinsimbi zensimbi nezinye izinto ezisebenza ngozibuthe.

1.Usayizi ohlangene nesisindo esincane

2.Quick futhi kulula ukusebenza nge ON/OFF uhlelo / isibambo

Idizayini yegroove emise okwe-3.V ezansi ivumela uzibuthe ofanayo wokuphakamisa ofanele izinto eziyisicaba neziyindilinga

4.Force powered by super-strong grade of rare earth Neodymium magnets

5.I-chamfering enkulu ezungeze ezansi ivikela ngempumelelo ukuthambeka kwendawo engezansi futhi ivumela isiphakamisa kazibuthe ukuthi sisebenzise ngokugcwele amandla ayo kazibuthe.

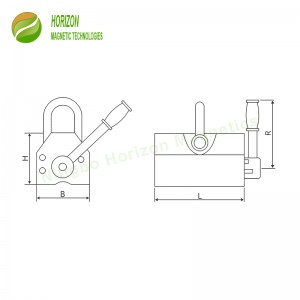

| Inombolo Yengxenye | Ilinganiselwe Amandla Okuphakamisa | Ubukhulu Amandla Okukhipha | L | B | H | R | Isisindo sengqikithi | Ubukhulu Bezinga Lokushisa Lokusebenza | |

| kg | kg | mm | mm | mm | mm | kg | °C | °F | |

| I-PML-100 | 100 | 250 | 92 | 65 | 69 | 155 | 2.5 | 80 | 176 |

| I-PML-200 | 200 | 550 | 130 | 65 | 69 | 155 | 3.5 | 80 | 176 |

| I-PML-300 | 300 | 1000 | 165 | 95 | 95 | 200 | 10.0 | 80 | 176 |

| I-PML-600 | 600 | 1500 | 210 | 115 | 116 | 230 | 19.0 | 80 | 176 |

| I-PML-1000 | 1000 | 2500 | 260 | 135 | 140 | 255 | 35.0 | 80 | 176 |

| I-PML-1500 | 1500 | 3600 | 340 | 135 | 140 | 255 | 45.0 | 80 | 176 |

| I-PML-2000 | 2000 | 4500 | 356 | 160 | 168 | 320 | 65.0 | 80 | 176 |

| I-PML-3000 | 3000 | 6300 | 444 | 160 | 166 | 380 | 85.0 | 80 | 176 |

| I-PML-4000 | 4000 | 8200 | 520 | 175 | 175 | 550 | 150.0 | 80 | 176 |

| I-PML-5000 | 5000 | 11000 | 620 | 220 | 220 | 600 | 210.0 | 80 | 176 |

1. Ngaphambi kokuphakamisa, hlanza indawo yokusebenza okufanele iphakanyiswe. Ulayini omaphakathi wezibuthe eziphakamisayo unomphela kufanele uhambisane nesikhungo samandla adonsela phansi ocezu lokusebenza.

2. Enqubweni yokuphakamisa, ukulayisha ngokweqile, abantu abangaphansi kwe-workpiece noma ukudlidliza okunzima kuvinjelwe ngokuqinile. Izinga lokushisa lomsebenzi kanye nezinga lokushisa le-ambient kufanele libe ngaphansi kuka-80C degrees.

3. Uma uphakamisa i-workpiece ye-cylindrical, i-V-groove kanye ne-workpiece kufanele igcinwe ixhumene nemigqa emibili eqondile. Umthamo wayo wokuphakamisa ungama-30% - 50% kuphela wamandla okuphakamisa alinganiselwe.